Glass and Glazing Shop Drawing Services

Glazing shop drawings are detailed technical documents that guide manufacturers, fabricators, contractors and installers in precisely fabricating, treating and installing the glass in any designed framework. These drawings take the designed aesthetic to a more structural accuracy.

What Are Glazing Shop Drawings?

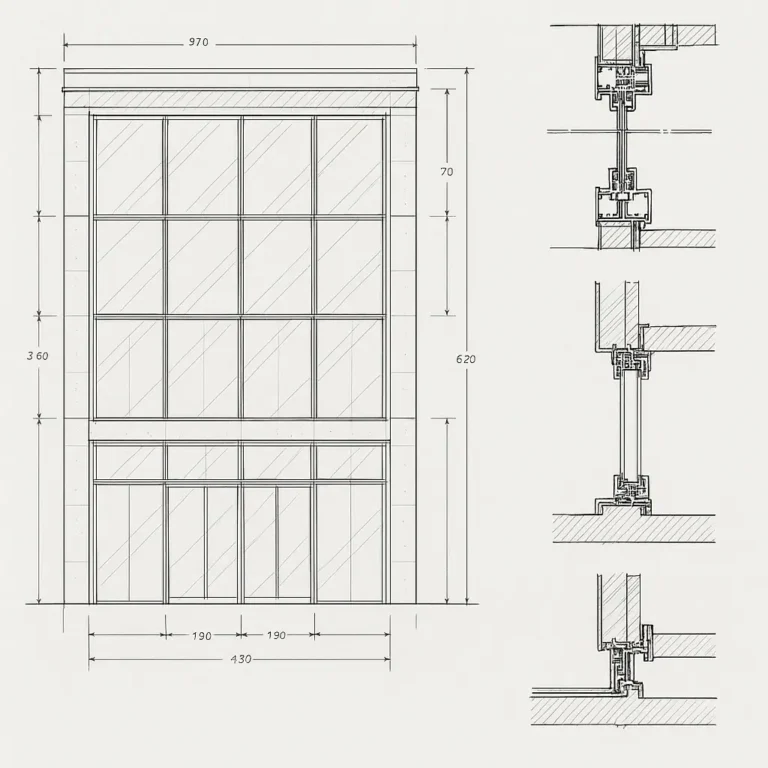

Glass and glazing shop drawings act as a technical guide for the accurate fabrication and installation of any glass element in a construction project. Unlike an architectural drawing, which focuses more on design, these drawings provide precise information for cutting, polishing, tempering and assembling of all glass components. Typically, they might include exact dimensions, material specifications with even information on coatings, hardware placements, anchoring systems and even compliance references. This level of detailing in drawings ensures that all the pieces manufactured are accurate and a perfect fit for the framework designed in the building system.

Glazing shop drawing services help a myriad of professionals on site, including architects, structural engineers, consultants, contractors, manufacturers and even fabricators. They all rely on these drawings for accuracy and installation in real-world conditions.

Typically used in storefronts, curtain wall systems, interior partitions, glass canopies and skylights, glass and glazing shop drawings act as an execution roadmap for glazing installations on site with precision, safety and efficiency.

Purpose of Glazing Shop Drawings

Glass shop drawings are essential, as even a minor measurement error in glass fabrication can lead to costly delays or complete rework. These drawings provide the technical details that help eliminate all such risks while minimizing any material wastage and controlling cost overruns.

Shop drawings also improve interdisciplinary coordination amongst everyone, including architects and engineers, fabricators and manufacturers, bringing everyone on the same page, ensuring that everyone is aligned from design to installation. Overall, it streamlines the whole process with clear installation instructions and manufacturing detailing, making every step efficient, less error-prone and faster.

Shop drawings also ensure all standards and compliance codes are followed thoroughly. Structural integrity is also ensured with the appropriate type of glass and hardware components. Further, in a few cases, an added advantage is enabling off-site fabrication of the components. This prefabrication support saves significant time during site execution and improves overall project efficiency.

Benefits of Glazing Shop Drawings

Explore how glazing shop drawings boost accuracy, efficiency, and coordination on-site.

Shop drawings include detailed and precise technical detailings for fabrication and installation, leaving no room for guesswork or assumption at any point

Having such details right from an early stage ensures any discrepancies and errors can be detected and corrected early – before any costly fabrication begins

The clarity amongst teams helps reduce material waste, unnecessary costs, rework and any site delays. It helps the project stay within the planned schedule and budget

Shop drawings act as a common reference document for all the involved stakeholders helping them stay aligned at all stages – from designing to execution

Exact and accurate specifications help manufactures produce specific glass pieces and components without any error, interruption or miscommunication

Beyond the fabrication process, it also becomes a detailed step-by-step visual and dimensional guide for installers to follow on-site for a faster and error free installation

The shop drawings ensure that all glass and glazing specifications are according to the design requirements and also wind-load resistance, deflection limits and structural codes, ensuring safety and structural integrity

Drawings are all prepared not only according to design intent and structural requirement but according to all local codes, fire safety norms and engineering standards

Key Features of Our Glass Shop Drawings Services

2D & 3D Drawings

We deliver high quality, precise 2D drafted drawings and 3D views to ensure accurate detailing and visualization for fabrication and installation.

Fabrication & Installation Details

The drawings become a guiding document with fabrication instructions including joinery, cutting patterns and hardware placement to streamline production

Load & Safety Compliance

We ensure the structural integrity of the glazing system is never compromised and it complies with all safety codes, including any local regulations for glazing systems

Complete Material Specifications

Every drawing we deliver includes all specifications, including glass type, framing details, sealants, fasteners, support systems and any other requirement, as per your project’s needs

Seamless Coordination

Our drawings make sure all stakeholders in the building system are aligned with each other and the design intent, to avoid any clashes and improve coordination

Accurate Dimensions & Tolerances

Height, width, thicknesses and even edge details are precisely calculated and defined according to the design, minimizing any errors during handling, cutting or installation

Our Process for Glazing Shop Drawing Services

The process begins with collecting and analyzing all architectural drawings along with understanding design intent to understand the glazing requirement. This helps us identify details such as glass type, thickness, coatings, structural loads, etc

The technical work begins. Using software like AutoCAD or Revit BIM, we prepare accurate shop drawings with all glass detailing including joineries, paneling layouts, dimensions with other required details

Draft drawings are shared with architects, consultants and involved contractors for multiple rounds of reviews. Everyone’s feedback is important, hence, incorporated promptly to ensure compliance and clarity.

Once approved by the stakeholders, we generate fabrication and site-ready documents which include cutting patterns, material specs and edge detailing, necessary to start the production

Beyond the fabrication process, our drawings are also used on-site by the installers as a step-to-step guide to ensure the right alignment, hardware placement and hence, the final installation

We offer complete technical support even post-delivery. This is to resolve any fabrication or installation queries that you might have and ensure a seamless and hassle-free experience

Why choose Cresire as Shop Front Glazing Company for Your Project

Proven Sector Experience

As a shop drawings services company, we have successfully delivered glass and glazing shop drawings for numerous commercial, residential, and retail projects across the globe including the USA, UK, Europe, and Australia

Detail-Oriented Glazing Drawings

We create highly accurate and coordinated glazing shop drawings that align not only with the architectural design intent but the structural requirement, minimizing on-site issues and any risks

Stakeholder Collaboration

Our team ensures a clear and seamless communication and coordination with architects, façade consultants, contractors, and installers to ensure everyone has clarity and the end product meets visual and technical requirements, both

Retrofit & Renovation Expertise

We support glazing upgrades for existing buildings using point cloud data or legacy CAD drawings , enabling precise retrofits with minimal disruption.

Advanced CAD & BIM Proficiency

Leveraging the latest CAD and BIM platforms, we deliver shop drawings with high geometric accuracy, clash detection, and seamless integration into digital construction workflows.

Cost and Time Efficiency

By reducing any errors or a need of rework or unnecessary material waste, our shop drawings streamline the whole process of fabrication and installation, making them time-efficient and faster

Retrofit & Renovation Expertise

We support glazing upgrades for existing buildings using point cloud data or legacy CAD drawings, enabling precise retrofits with minimal disruption

FAQ's

What information is included in glazing shop drawings

They include detailed specifications of the glass types, thickness, coatings, materials, framing and paneling systems, joineries and any other details required for fabrication and installation of the glazing system in the project

What software is used to create glazing shop drawings?

Typically used software for the shop drawings include AutoCAD and Revit, as a BIM-enabled tool. These software help drafting highly precise and accurate drawings for execution.

How do glazing shop drawings help reduce project delays?

Glazing shop drawings help eliminate any miscommunication or errors at any stage of process by providing clear fabrication and installation details. This reduces rework, minimizes on-site errors and ensures smooth collaboration - ultimately saving time

Are these drawings required for all types of buildings?

Yes, shop drawings are essential for all building types including residential, commercial or industrial. Any building where glass installation is required. https://cresirendering.com/blog/bim-for-residential-construction/