What is Clash Detection?

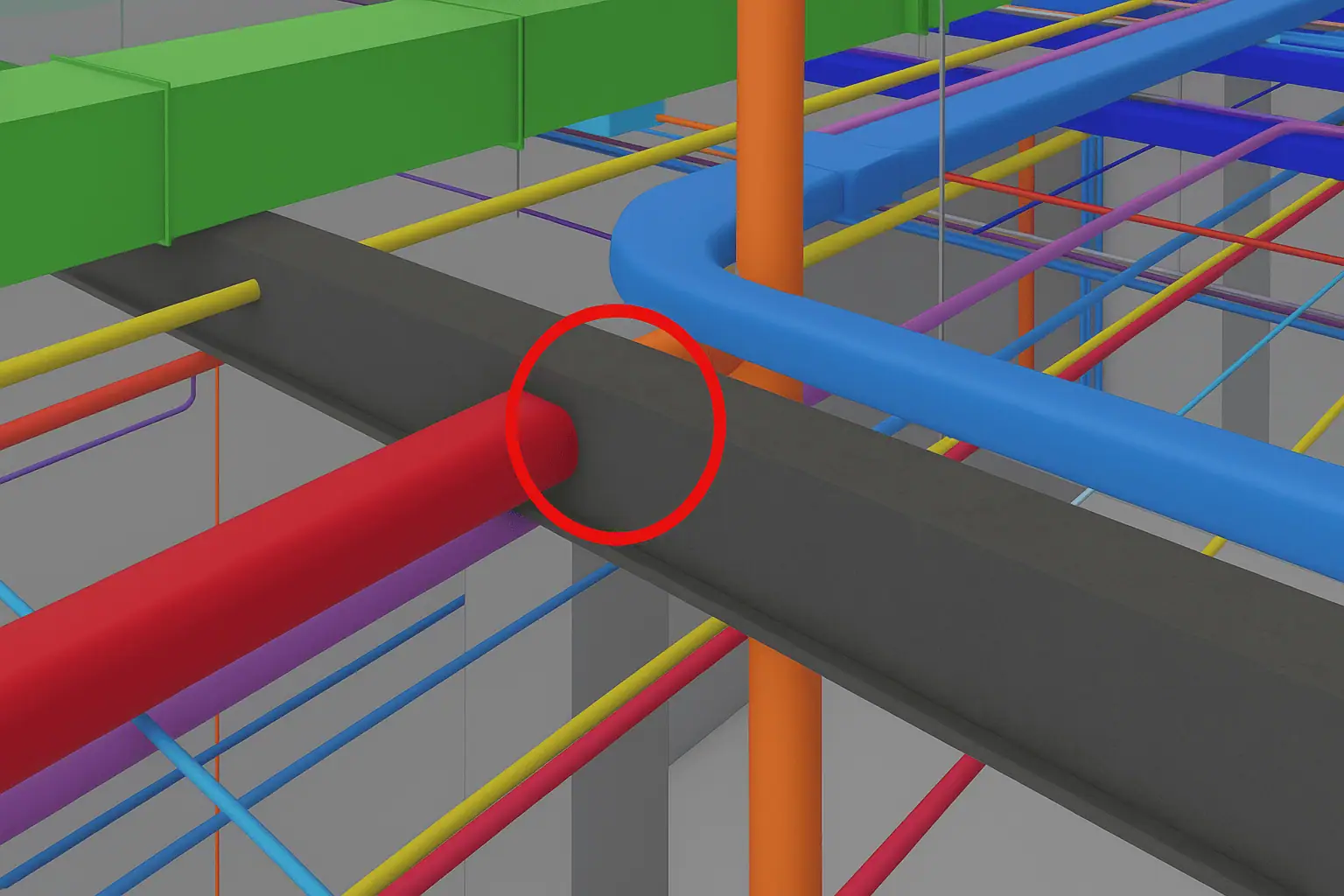

Clash Detection in any Building Information Modeling (BIM) is the process of identifying and resolving any conflict or interference that might have occurred between various building systems – architecture, structure or MEPf (Mechanical, Electrical, Plumbing and Fire Protection) – within a shared coordinated 3D model. These clashes are usually a result of multidisciplinary work on a single project which might overlap or be incompatible with each other.

The overall concept of clash detection might not be new in the AEC industry but the stage at which it occurs has changed the whole game drastically. Earlier such clashes would be discovered on-site, making the rectification much harder, costlier and time-consuming. Now, with the advancement of BIM tools and software like Navisworks and Autodesk Revit, AEC professionals can detect inconsistencies, overlaps or potential disputes amongst various systems, before any construction begins. This early detection with complete visualization of the projects helps them improve their coordination, reduce any construction risks and enhance overall efficiency of the workflow.

To understand clash detection in the practical world, let’s consider an HVAC duct intersecting with a structural beam. Without any BIM clash detection, this error would be evident only while installation on site as all stakeholders work separately with only periodic communication. However, a well-coordinated 3D BIM model would have saved the day – detecting such overlaps early in the project, it would have ensured enough time for redesign and smoother execution.

What Causes Clashes in BIM Models?

Clashes in BIM models typically occur when all the systems – architectural, structural and MEPf, integrate their own models into a single 3D federated model. Since all disciplines often work separately, using their own tools, formats and design expertise, discrepancies are bound to occur during coordination. BIM models just fast-track the process of detection. Here are a few common causes:

- Lower Level of Detail (LOD) or an underdeveloped model lacking precision and detailing

- Design assumptions with placeholder elements as a result of guesswork

- Insufficient time deadlines for complex geometries which increases the possibility of overlaps

- Relying completely on 2D drawings or images for such 3D models

- Coordination gaps due to miscommunication or outdated tools with incompatible software

- Insufficient soft clash analysis, where required tolerances for maintenance and operation are ignored

- Skipping periodic clash reviews with sufficient time given for analysis

- Software or file incompatibility amongst teams can cause data loss during merging

- Inexperienced BIM modeling team with a lack of BIM literacy or poor management can cause issues across disciplines.

Types of Clashes in BIM

In any BIM workflow, smooth and continuous coordination across disciplines is critical to ensure the success of BIM. It cannot succeed in isolation. But when designs of these disciplines merge, they can create the following three main clashes:

- Hard Clash Hard clashes involve two or more building elements occupying the same physical space in the built – causing a direct conflict. For example, a plumbing pipe might be laid by the MEP team that crosses the concrete beams, resulting in a hard clash. These are more physical clashes, which, if not resolved, might later cause costly on-site reworking.

- Soft clash: Soft clashes are less physical but more preventive measures – ensuring that the design is not only buildable, but also functional and maintainable in the long run. These refer to issues related to insufficient buffer zones or tolerances for each element. A common example would be to place an air-conditioning unit near to a wall with no room for maintenance access. These are often related to safety, functionally or code compliance and can be detected using rule-based checks in software like Navisworks or Solibri.

- Workflow or clearance clashes: These are also known as the 4D clashes – referring to the usual schedule or sequencing-related conflicts. For example, if the scaffolding for the building is planned after its facade installation or HVAC installation is scheduled before structural casting – these create timeline issues for the project and its buildability. Avoiding any resource and time conflicts, 4D clash detection reduces on-site delays and aligns the BIM model with real-time project scheduling.

How are Clashes Detected and Resolved?

Clash detection in any BIM workflow begins with integrating 3D models as designed by various disciplines – architecture, structure, MEP and any other project-specific teams. These models are converted into one unified federated model through coordination usually done in Autodesk Revit, Navisworks or Solibri. With a unified model, the software can start scanning for any clashes that might be present amongst the teams and their design. This includes any physical clash – hard or soft clashes or any scheduling-related 4D clash.

Once identified, these clashes are highlighted and shared in the form of a detailed report with the concerned teams. One example would be if a fire sprinkler runs through a concrete beam, the structural and MEP team will receive a report for them to redesign and reiterate. They will need to redesign their elements and routes and resubmit their updated models. This step is repeated and the BIM model is reanalysed until all clashes are finally resolved. This can be a long process as teams redesign, rethink and iterate new versions of their designs till all their elements are compatible – physically, technically and time.

To keep the workflow smooth, model coordination meetings need to be held regularly, allowing stakeholders to review models together, agree on resolutions and realign their timelines. Using tools like Navisworks’ Clash Detective or Solibri’s rule-based checking, teams can simulate changes and ensure coordination in real-time. By resolving clashes during the design stage with BIM Level 2 protocols, teams can achieve better accuracy, communication and an efficient construction process right from the beginning.

Benefits of BIM clash detection

BIM clash detection has many direct benefits to your resource, cost and time management. However, here are six more key benefits that can contribute to a more efficient project execution:

- Prevents Construction Rework and Cost Overruns

With early clash detection, it helps avoid any costly reworking on-site, material wastage or unnecessary delays. It can resolve clashes within teams during the design stage – saving upto 70% of time and resources lost to design-related errors. - Enhances Interdisciplinary Coordination

A BIM unified model integrates various system models in a centralized 3D environment. It allows all stakeholders involved to visualise the project together with clarity in a unified model. Tools like Navisworks enhance real-time coordination, minimize communication gaps and align everyone to the project. - Increases Accuracy in Fabrication, Installation and Construction

Clash-free 3D BIM models produce precise drawings for off-site fabrication and on-site installation or construction. Dimensions are accurate, which reduces the guesswork and material wastage while speeding up an error-free assembly and construction. - Boosts Project Efficiency with 4D Planning

With 4D BIM tools like Naviswork Timeliner in hand, AEC professionals can visualise construction sequencing, equipment movement and delivery timelines better and quicker. This time-based simulation helps in avoiding any workflow clashes between stakeholders, ensuring the project timeline. - Improves Safety through Visualization

Advanced visualisation tools allow professionals to explore the 3D project model before it reaches on-site for construction. This helps workers understand the spatial arrangement and design, avoid any hazards and plan for safer operations, following all safety protocols. - Optimizes Resource Allocation and Material Use

Clash-free BIM models can easily generate accurate BOQs and BOMs, which can further help in precise planning of material, labor and equipment. This helps in rescuing procurement errors, material shortage or wastage, cost overruns and overall keeps the project on track – financially and environmentally.

How Cresire helps in Clash Detection & resolving

At Cresire, we continue to help AEC professionals avoid any costly errors through top-quality BIM Clash Detection services. With advanced tools like Autodesk Revit and Navisworks, our team of experts carefully reviews your 3D models, across disciplines to detect all kinds of clashes – hard, soft or workflow. We ensure all elements are well-coordinated before your project reaches the construction stage – saving your time, cost and rework.

With a clear collaboration between all stakeholders, we create a clash-free 3D model that can develop detailed BOMs, BOQs and GFCs drawings – anything you need for your project. Whether you’re planning a residential project or a large commercial building, Cresire ensures smooth coordination and better on-site execution through high-quality clash-free 3D BIM models.

Struggling with unresolved clashes in your BIM project? Reach out to Cresire today to build clash‑free BIM models with confidence