Mechanical contractors have been struggling with similar issues for ages – construction starts on-site, main HVAC duct ready to be installed and that’s when you find a beam running exactly where the duct needs to go. This isn’t only annoying – it’s really expensive. This is where BIM services for mechanical contractors become a game changer.

A building’s mechanical systems, from HVAC to plumbing lines to electrical layouts, all can be visualised in a data-rich BIM 3D model – all integrated with the architectural and structural systems. BIM services help contractors detect issues as early as the design phase, improving collaboration, avoiding any rework and delivering projects on time and within budget.

What Is BIM for Mechanical Contractors?

BIM for mechanical contractors is more than just a 3D model to visualise – it’s an intelligent workflow that facilitates greater coordination. It integrates mechanical systems – including HVAC equipment, ductwork, piping networks, and plumbing fixtures, complete with technical specifications and performance data, with architectural, structural, and electrical designs in a single, coordinated, optimized model.

From design phase to fabrication, installation and even facility management, BIM modeling for mechanical systems ensures that layouts are visualized before installation, coordinate with other disciplines, detect conflicts and even generate accurate fabrication or construction-ready drawings with quantity take-offs. This process reduces uncertainty, improves efficiency and keeps projects running smoothly from concept to completion within time and budget.

Key Benefits of BIM Services for Mechanical Contractors

- Enhanced Design Accuracy & Coordination

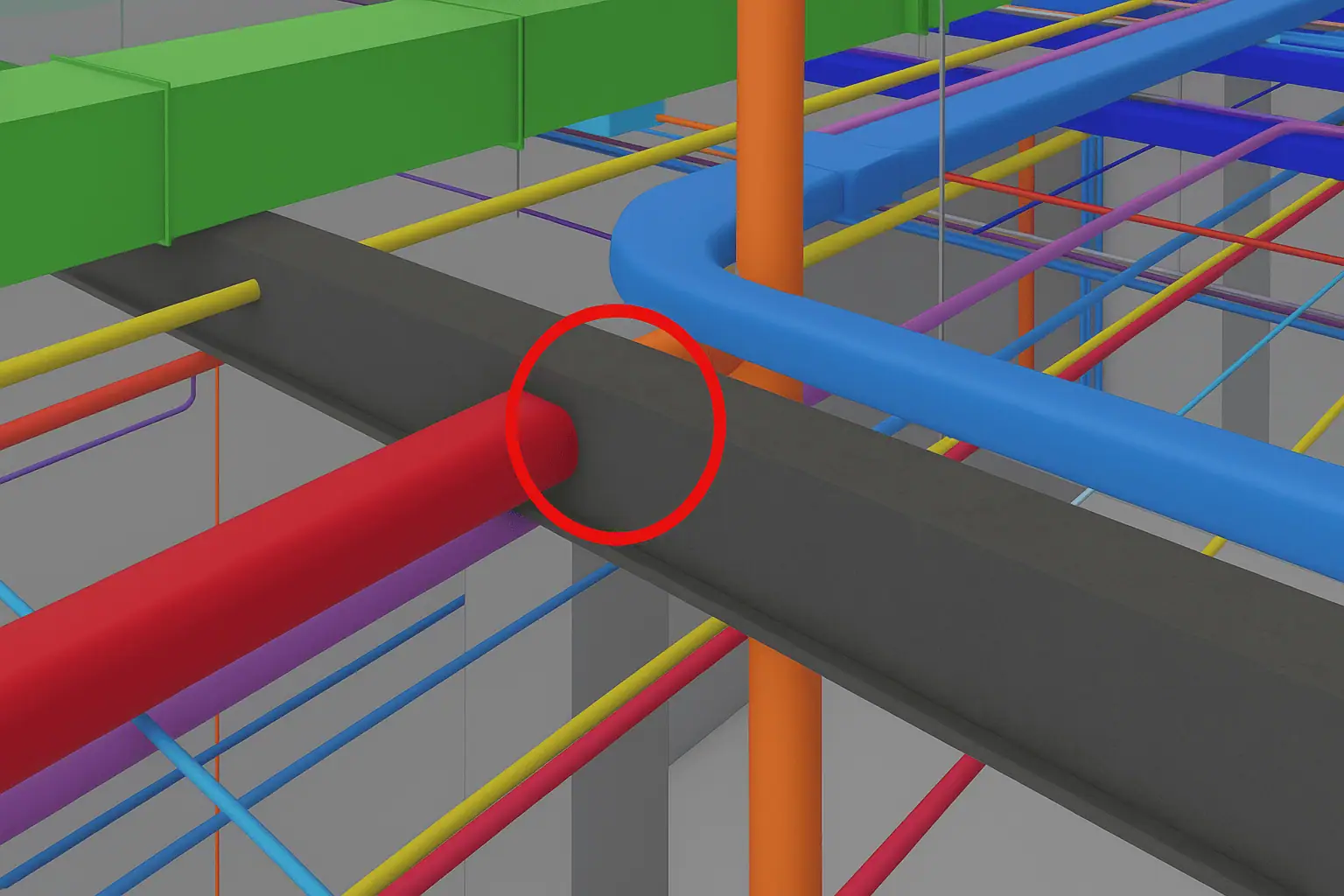

With all building systems in place right from the beginning, BIM coordination services helps all stakeholders spot and resolve clashes together with real-time interdisciplinary coordination. This helps avoid costly conflicts, reduces RFIs from the site and maintains the project schedule with no reworking. - Comprehensive Clash Detection and Risk Mitigation

We’ve all been there, when maybe the HVAC layout gets installed perfectly, but then the electrician shows up and now there’s a conduit running right through the return air duct. With BIM clash detection, these clashes get highlighted before any construction begins – MEP systems are integrated with structural and architectural elements, reducing any chance of costly last moment installation issues. - Cost & Time Efficiency

Take offs become accurate instead of educated guesses. Intelligent, detailed BIM models help in the accurate calculation of quantity takeoffs, preventing any material shortage or wastage. Moreover, with 4D scheduling in place, project timeline and scheduling become more optimised, making the project overall cost and time efficient. - Enhanced Collaboration & Data Sharing

The Common Data Environment is simply a shared workspace where changes happen in real time with real stakeholders involved. When you update any ductwork layout, the structural team sees it instantly. There remains no chance of miscommunication and only quicker and reliable decisions. - Improved Visualization & Decision-Making

See in three dimensions what you are building. Relying on 2D drawings to configure complex mechanical systems with technical structural elements can be a nightmare. A BIM 3D model helps in a much clearer visualization, better communication and hence, faster approvals and decisions. - Lifecycle Value & Maintenance Support

With BIM, your drawings become living documents with embedded data about every element of each building system. Now, your facility manager can create better, cost-effective maintenance plans and maintain mechanical systems more effectively for years.

Industry Applications of BIM for Mechanical Contracting

BIM’s adaptability makes it a powerful tool. You can use it to bring together HVAC, plumbing, and piping systems in one digital model, which helps manage complex jobs, work more efficiently, and meet code requirements on projects big and small.

- Residential Projects

From single-family homes to apartment buildings, BIM lets you plan better and optimized HVAC layouts, design mechanical rooms that don’t waste space but are still easy to access and create residential systems that save energy while being simple to maintain in the long run. - Commercial Buildings

Commercial Office buildings, retail centers and mixed-use projects have complicated mechanical layouts that need to fit around beams, walls and all other building elements. BIM helps you work out these details, making tenant build-outs and future upgrades possible with ease. - Healthcare Facilities

Hospitals, clinics, and labs – all need high accuracy and precision for systems like medical gas lines, clean air zones and ventilation – which can’t fail in any scenario. BIM helps your project meet all health regulations while ensuring the safety and reliability. - Educational & Public Infrastructure

Schools, colleges, and transit buildings need mechanical systems that last a long time. BIM ensures optimized mechanical systems with planned easy accessibility and lifetime maintenance.

Essential BIM Tools and Standards for Mechanical Contractors

Picking the right BIM software is crucial for any mechanical contractor to achieve accurate end results, work efficiently and coordinate effectively with other disciplines. One of the most essential BIM tools helping today’s AEC industry is Autodesk Revit, which works best for designing and modeling mechanical systems. It provides you with detailed 3D views of all mechanical layouts, enhancing coordination and showing clients what’s actually planned. On the other hand, AutoCAD is still used for all those detailed 2D drawings – from system plans to detailed drafting works. Going further in the BIM workflow, Navisworks does clash detection and helps coordinate with other trades, so you can find and fix problems before they cause delays on the job site. Fabrication CADmep, another advanced tool, creates detailed shop drawings for you, supporting fabrication workflows with exact measurements. These tools work together to create a complete digital process from early design through installation.

Good software needs good standards to guide the work. Mechanical BIM projects should use specified Levels of Detailing (LODs) while following industry standards to keep everyone on the same page. LODs can range from 300 to 500; LOD 300 would mean a model with enough detail for design review and clash detection, LOD 400 would include fabrication details with exact specifications and lastly, a LOD 500 model would be as-built with complete information embedded. Following recognized standards like the National BIM Standard – United States (NBIMS), ISO 19650 series or others, keeps your work consistent, high-quality and compatible with other project teams’ workflows. These practices help mechanical contractors meet project goals without extra hassle.

Kickstart Your BIM Journey with Cresire rendering

At Cresire, we have spent years perfecting our BIM services for mechanical contractors that actually work in real-world conditions, helping mechanical contractors in today’s fast paced construction world. Our multi-trade coordination, along with skilled BIM modeling expertise, ensures all mechanical systems integrate properly with structural elements with no clashes. Moreover, our fabrication-level modeling produces shop drawings that manufacturers can use immediately and point cloud to BIM conversions that help your retrofit projects achieve new construction precision.

Our focus has always remained on delivering efficiency, cost savings and risk reduction while improving your construction and building performance. Whether you’re starting new construction or managing a complex retrofit – from residential to commercial or industrial, we ensure your mechanical systems get modeled, coordinated and executed with precision and long-term value.